- HOME

- Cosmetic OEM Lab

AIt is almost every day that we receive inquiries about facial sheet masks from our clients from various countries of the world.

AIt is almost every day that we receive inquiries about facial sheet masks from our clients from various countries of the world.

In this article, we will thoroughly explain details of facial sheet mask OEM production in Japan such as materials in use, MOQs, and costs for first-timers.

Contents

In the past, facial sheet masks were considered to be more like “special care” items but this has been changing as there in an increasing number of people who use them on a daily basis.

If we were to think of 3 reasons why they are as popular as they are:

We are sure different people have different reasons to like them but these are probably generally applicable reasons.

Now, we would like to take a look into the level of demand for facial sheet masks.

Let’s take a look at what the domestic market is like for facial sheet masks in the country.

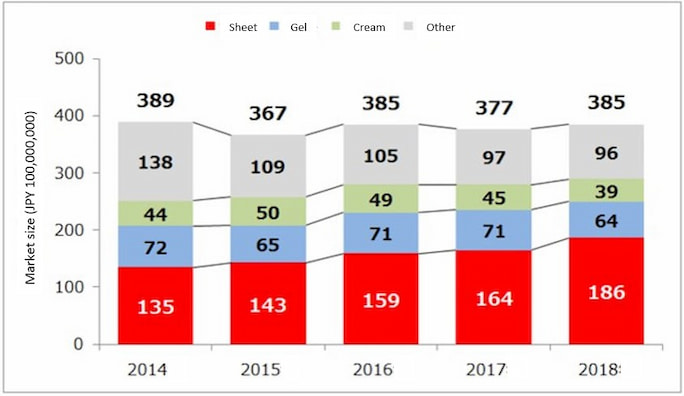

The graph below is based on 2019 data provided by The Shogyokai Publishing Co., Ltd.

It shows the market size for ‘pack’ products including sheet masks.

As it can be seen, the only segment in the list that is growing is sheet masks. We think it is safe to assume that number of users is increasing each year as well.

However, we believe the main reason why the market for facial sheet masks is growing in the country is that it became an ‘every day’ item.

As demand keeps growing, so does supply as more and more people and companies want to get their own sheet mask OEM products in the market.

So, the market for facial sheet masks in Japan has been consistently getting larger but what is the situation overseas?

Actually, it has been growing worldwide, global market size being 1.16 billion USD in 2018. As the average annual growth is measured at 10.94%, it is expected to reach 1.94 billion USD by 2023.

Even though the market is also growing in other areas as well, the spotlights stand on Asia-Pacific which accounts for 67% of the total market.

We actually get a majority of our sheet mask inquiries from Asian countries as well.

As the market kept growing, innovations kept happening too and different types of products hit the market.

We would like to divide facial sheet mask types into 3 categories and take a deep dive in each:

The material of the sheet probably has the biggest impact on how the product feels on the skin.

Below are 3 commonly used sheet materials:

These are the most commonly used materials on the list. All 4 are plant-derived and quite easy on the skin, as they are not known to cause any inflammation. Their biodegradability is also another positive.

This is a relatively rare material with a lot fewer products and users. Simply put, they are skin-care ingredients made into the shape of a mask by jellifying and they melt in hot water. Although there are full-face hydrogel masks, it is more common to see eye masks.

Biocellulose is a natural fiber that is derived from coconuts and it is known for its strong affinity to water. Its hydration and adhesion properties are second to none.

Biocellulose masks used to be very popular in Japan in the past but they are far from being widely used today as their high prices make them a tough sale.

There are many different shapes of facial sheet masks. We think they could be divided into 3 categories:

These make are basically flat like regular paper when spread and have no three-dimensional structure. As they are the cheapest options, vast majority of the products in the market consist of 2D Masks.

These are masks with a three-dimensional structure based on the human face. They have better adhesion than 2D masks yet price is considerably higher, which is why they are a lot less common in the market.

These are masks divided into different parts of the face. Their biggest advantage is the ability to apply different ingredients to different parts of the face. On the other hand, they are expensive to manufacture and also less convenient from the user’s perspective.

We talked about materials up until this point. Facial sheet masks also have different formulations and effects. In Japan, the following are the 3 main categories of sheet mask formulations:

These are sheet masks with formulations containing whitening ingredients such Tranexamic Acid, Vitamin C derivatives, Arbutin, etc.

Retinoid, Peptides, Alpha-Lipoic Acid are some examples of ingredients used in these formulations. The main purpose of these masks is to firm and lift the skin.

As a matter of fact, all sheet masks have a moisturizing effect but these formulations focus mainly on it. Ceramides, Collagens, and Hyaluronic Acid are often used as main ingredients.

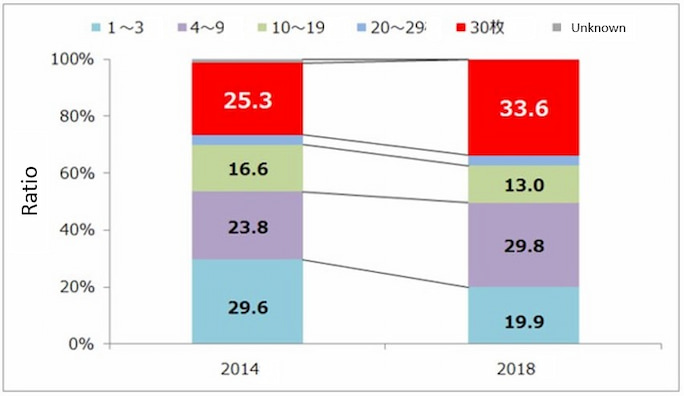

There are 3 commonly used packaging patterns of facial sheet masks:

This is the packaging method with one facial sheet mask in one aluminum sachet. They are often printed and can be with or without an outer box.

This is the packaging method where multiple facial sheet masks are put together in one aluminum sachet.

It can be anything from 2 sheets to 30 sheets. Aluminum sachets often have zip locks that enable the user to open and close when desired.

These products played a big role in bringing the cost of sheet masks which lead them to become everyday items.

This is the sort of packaging where individually packaged sheet masks are bundled together, usually in an outer box. Common examples are 3 packs, 5 packs, and 10 packs.

Up to this point, we tried to explain the market for facial sheet masks and technical details about different types of products. From this point on, we would like to explain the steps to create your own facial sheet mask OEM brand.

This should vary from company to company but we will try to draw a general image.

What material will the sheets be? If it’s cotton, what about the thickness? How many colors on the aluminum sachet? Or will you use a label instead? What about a box? These will need to be determined first, in order to get accurate pricing.

The best way would be to choose from the samples that OEM company has to offer.

Once the materials are determined, the formulation will need to be finalized. Many OEM companies should offer prototype productions free of charge. On average, a prototype should be ready in 2 weeks.

After the first prototype is ready, the buyer will get to test and give feedback to the manufacturer. It is very rare that a product passes in the first prototype so, you should feel free to ask for changes you think should be made and go for a second or even third prototype when necessary.

When all materials, packaging, specification details are determined and the formulation is finalized, the manufacturer will provide the client with a final quotation. After the buyer issues a purchase order, production will take a start.

Fortunately, facial sheet mask OEM production is a lot faster than other products. It takes 1-2 months for the product to be delivered after executing the order.

So, when you actually create your own facial sheet mask OEM product via a Japanese company, there will be certain costs to it.

First, MOQ for sheet masks is mostly 3,000 pcs but there are some companies that also take orders from 1,000 pcs.

However, when the order quantity is as low as 1,000 pcs, the price per piece gets unreasonably high so it is beneficial to think it as 3,000 pcs.

Individual Packaging

| Quantity | 3000 | 10,000 | 30,000 |

| Bulk Cost | 80 | 55 | 45 |

| Material Cost | 70 | 60 | 50 |

| Price per piece | 150 | 115 | 95 |

| Total Cost | 450,000 | 1,150,000 | 2,850,000 |

*Currency is JPY *No outer box *Nonvowen fabric sheet material

Multiple Sheet Packaging

| No. of Sets | 1000 | 3000 | 10,000 |

| Bulk Cost | 300 | 250 | 200 |

| Material Cost | 350 | 240 | 220 |

| Price per piece | 650 | 490 | 420 |

| Total Cost | 650,000 | 1,470,000 | 4,200,000 |

*Currency is JPY *No outer box *Nonvowen fabric sheet material

As can be seen on the tables, in the case of individual packaging, starting cost is around 150 JPY/piece at 3,000 quantity.

In Japan, the average retail price of facial sheet masks is estimated between 1800-2000 JPY. This includes both individually packed single products and multiple sheet packs.

Feel free to use our Automatic Quotation Tool.

However, the price will be highly dependent on actual materials, specifications, and ingredients. For an accurate quote please contact us via the Inquiry Form.

Lastly, we would like to introduce you to 3 points why we think we could be a good fit for you.

It is a fact that most people want to start with small lots as they don’t want to take big risks or simply don’t have the capital.

In OEM Co., Ltd., we’ve always been cooperative with our clients who order in small lots. We take pride in our flexible correspondence and cost-effective solutions for low quantity orders.

As we don’t have our own factory, we get to have access to a countless number of different formulations and product types.

Also, we have been assisting our clients with various types of facial masks from hydrogel to biocellulose. In addition to that, we are also able to manufacture sheet masks other than face masks, such as eye sheets and body masks.

In OEM Co., Ltd., we value delivering the product our clients have in their minds. For this reason, we always take the extra step to go through long and challenging R&D processes with multiple prototype productions, free of charge.

In this article, we tried to explain the key points of facial sheet mask OEM production in Japan.

If you wish we provided you with further information, please feel free to contact us via the button below.

Inquiry

OEM vs ODM Explained

2026.1.24

For further information, please contact us.