- HOME

- Cosmetic OEM Lab

The cosmetic market has been growing in every corner of the world with a constantly increasing number of products and sales and Japan was no exception.

The cosmetic market has been growing in every corner of the world with a constantly increasing number of products and sales and Japan was no exception.

In this article, we will talk about how the private label cosmetic industry is in Japan, and how it compares to previous years. Then we will take a deep look into what kind of private label cosmetics companies there are in the country.

Contents

As Japanese are one of the most skin-conscious nations in the world, the cosmetic industry is a big one accordingly as well.

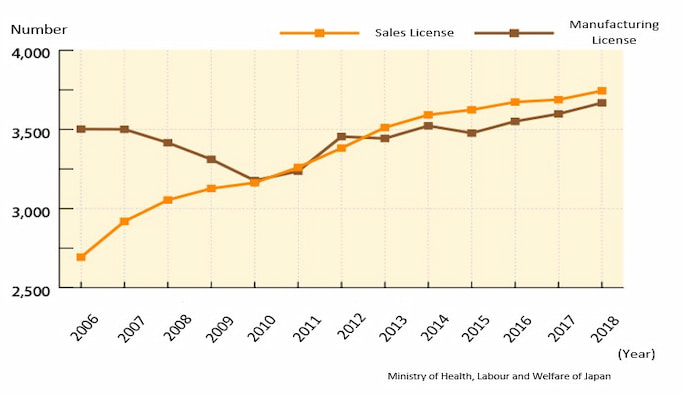

The graphic below shows how many companies in Japan have a ‘sales license for cosmetics’ and how many have a ‘manufacturing license for cosmetics’. The numbers were 3744 and 3668 respectively, as of the end of the 2018 fiscal year.

Of course, this does not exactly mean that there are 3668 private label cosmetic factories in Japan. There are a lot of companies who have this license and follow a ‘fabless’ business practice which means they outsource their productions to private label cosmetic manufacturers.

But it is also a fact that this could give an idea of how many people could be using private label cosmetic manufacturers throughout the country.

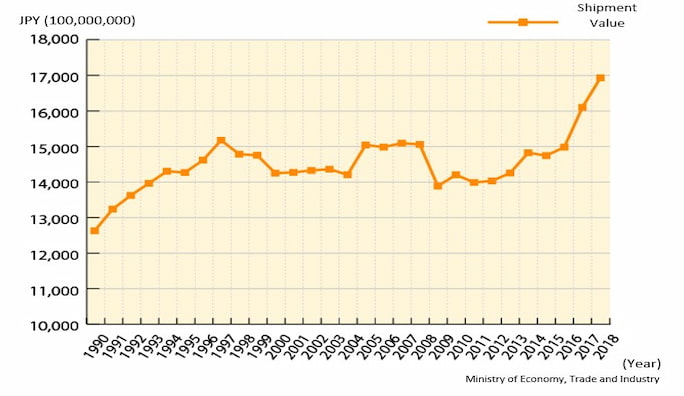

Another data reveals that private label cosmetic manufacturers in Japan collectively made a total of shipments that are measured at 1,694.2 billion yen (Approximately 15.5 billion USD) which compares +5.2% to the previous year.

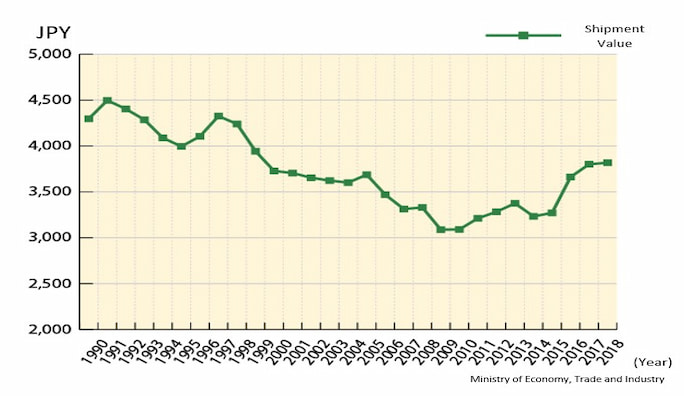

What about the cosmetic product prices? According to the graph below, the average price per kilo (Approx. 35.3oz) has been rising consistently for over a decade, although it is far from that of the 1990s.

As you can see, the private label cosmetic industry in Japan has been growing steadily as a whole with a rising number of companies and retail prices.

Up until this point, we took a brief look at the industry from the perspective of numbers.

Now let’s see what type of companies you will encounter in Japan while looking for a private label cosmetic manufacturer.

These are the manufacturers that actually operate their own fabrication facilities. Some of them may have their own cosmetic brands in the market but it is more common they focus on manufacturing private label products for other brands.

Here are the 2 advantages of manufacturers that operate their own production facilities:

When you manufacture a cosmetic product at your own factory, the cost consists of materials, utilities, and labor. This allows you to have full control of your prices and provide competitive prices when necessary.

Another advantage is that manufacturers who operate their own factories often hold all intellectual property of a formulation and keep it to itself as an industrial secret.

Although manufacturers who have their own factories have undeniable competitive advantages, they also come with some challenges.

It is not hard to imagine it wouldn’t be cheap to obtain a massive building and fill it with expensive manufacturing equipment, especially in a country like Japan.

It is also a given that fixed costs as utilities, equipment maintenance, and labor could be quite overwhelming.

Of course, it is still quite profitable in the long term as long as there is a desired level of production. However, it is certainly safe to say that it is an investment that will take decades to break even.

Simply put, these are companies who often hold their own ‘manufacturing license for cosmetics’ and are legally allowed to put their names as the manufacturer of the product.

However, they actually stand in the middle of the client, and the manufacturer, ultimately outsourcing the manufacturing of the product.

This could be a rare business model in the world but it is fairly common in Japan since it holds advantages to itself.

Especially considering the fact that most manufacturers in Japan do not export directly, have English-speaking staff, or are not keen to take new business with small MOQs, there are quite a few reasons why these fabless companies exist.

The biggest advantages of this business model are following:

When you have your own factory and produce everything there, you are limited to your equipment and technical abilities.

As fabless companies often work with tens of different factories, they are able to outsource any kind of product to those factories on a case-by-case basis. This allows them to produce almost any kind of product ultimately leading to a sufficient one-stop service.

Also, not having to establish and operate a factory keeps the initial costs to start the business very low and it is often possible to maintain the business with less than a dozen of employees.

We could say that there are mainly 2 disadvantages to fabless cosmetic OEMs:

This goes without saying but, fabless manufacturers have to add up their profit margins to the prices they get from factories. This puts their pricing significantly above companies that own their factories.

In order to make up for the price disadvantage and stand as a valuable option, fabless companies need to be very good at their service offering conveniences such as being a one-stop solution and having the ability to make strong proposals.

These are factories that aim to widen their service by outsourcing the products they are not able to produce at their production facilities.

They are not as aggressive and inclusive with their outsourcing as fabless OEM companies but they have some certain products in their portfolio that they do. An example would be a skin-care specialized factory outsourcing their production for mascara.

When a company is limited to its production capacity or equipment, there will be products that it will not be able to assist its clients with. Outsourcing a selection of products will reduce the frequency that this happens significantly.

As a natural result, it will also boost company revenue to some extent.

When an OEM company produces a product in its own factory, the manufacturing cost will basically be labor and raw materials which will give the company a wide headroom to determine its pricing. However, when the product is outsourced to another factory, it is a different story since they will need to add their profit margins on the price they get from the other factory. This will result in an inconsistency with pricing since outsourced products will be significantly more expensive than in-house ones.

However, it is not just pricing. As all factories are different, there could be a difference in the product quality and characteristic which could come as unpleasant to some clients.

There are a lot of different types of cosmetic products in the world such as skin-care, makeup, hair-care, and UV cair products as well as many others. It is very rare to see a company that is capable to produce everything.

Even if they are, they are often not equally good at manufacturing products of each category. It is also not rare to see companies that only manufacture products from one category and put their expertise on it.

These are companies that specialize in skin-care products such as creams, lotions, and milks, etc. They can also divide into different specialties based on product types, such as packs or sheet masks.

These are companies that specialize in so-called color cosmetics such as, lipsticks, mascaras, eyeliners, BB creams, foundations, and so on. The number of these companies is very low in the country and MOQs are significantly higher than that of skin-care products.

These are companies that mainly produce hair-care products such as shampoos, conditioners, tonics, packs and gels, and so on. There are companies that also produce skin-care but it is fairly common to see hair-care only companies.

The concept of cosmetics is very wide and inclusive in Japan. Daily necessities like soaps, shaving foams, toothpaste, and many others such as pet-care products are also included in this definition.

There will also be companies that specialize in any of these fields, offering their OEM production to the audience.

Although the core purpose of the product is what it holds inside, it is also undeniable that how a product appears and feels on the outside has a great impact on how it’s received by the purchaser.

Packaging design also plays a massive role in the product concept. This puts packaging manufacturers in a strong and important position in the industry.

In addition, raw materials can add to the value of the product quite a bit too, which is the reason why many raw material manufacturers constantly try to keep innovating with different combinations and brandings.

There are many different types of containers in the market. Jars, tubes, pumps, sprays, dropper bottles, and the list could go on forever.

As the container plays a huge role in the product image, it is not rare to see clients who care and spend more for it than the formulation itself.

Japanese factories often do not accept containers from overseas, and this results in a majority of containers used for cosmetic OEM production to be Japanese-made. This, unfortunately, results in high costs, however, there are companies that also import and sell Korean and Chinese-made containers in addition to their own.

Even though it adds to the cost, many brands believe that adding a box to the product increases its premiumness significantly. There are even rare cases that the other package is by far the most expensive element in the product including the formulation itself.

It is not just boxes, however. Aluminum sachets for sheet masks, sticker labels, etc. are also included in this category.

Raw materials are very important in the efficacy and marketing of the product. Raw materials are offered to the market by expert companies that conduct experiments and studies for years.

In Japan, these companies do not sell their products to manufacturers directly. Instead, there are trading companies that specialize in raw materials.

We would like to introduce 3 points of why we think we could be a valuable business partner for you.

As we are a fabless company that has a ‘manufacturing license for cosmetics’ and ‘manufacturing license for quasi-drugs’, we work closely with over 40 factories throughout the country.

As we are aware of what each country is good at and whatnot, we are able to outsource the right product to the right factory each and every time.

Since we have been working with a very wide range of cosmetic products, we have access to countless numbers of formulations, materials and concepts that allows us to offer the right product for you.

As we understand the risks to start a new business and create a new brand, we do our best to offer our help to those who want to start with small quantities.

Since we have been a company that has always had clients who start and continue with small quantities, we have the flexibility and means to offer a wide range of products at reasonable costs.

We are able to carry out production for a wide range of products from makeup products to hair-care products, pet-care, body-care and so on. However, we also offer a whole service when it comes to packaging and raw material elements as well. We do our best to find suitable materials in the market and offer those to our clients. We also often procure additional raw materials on behalf of our clients and store them as well.

In this article, we tried to explain the general lines of the cosmetic OEM industry in Japan and went on to introduce 3 points why we think we are a suitable option as a partner.

We always look forward to hearing your inquiries.

Inquiry

For further information, please contact us.